Quality | Machining issue from supplier

Quality | Machining issue from supplier

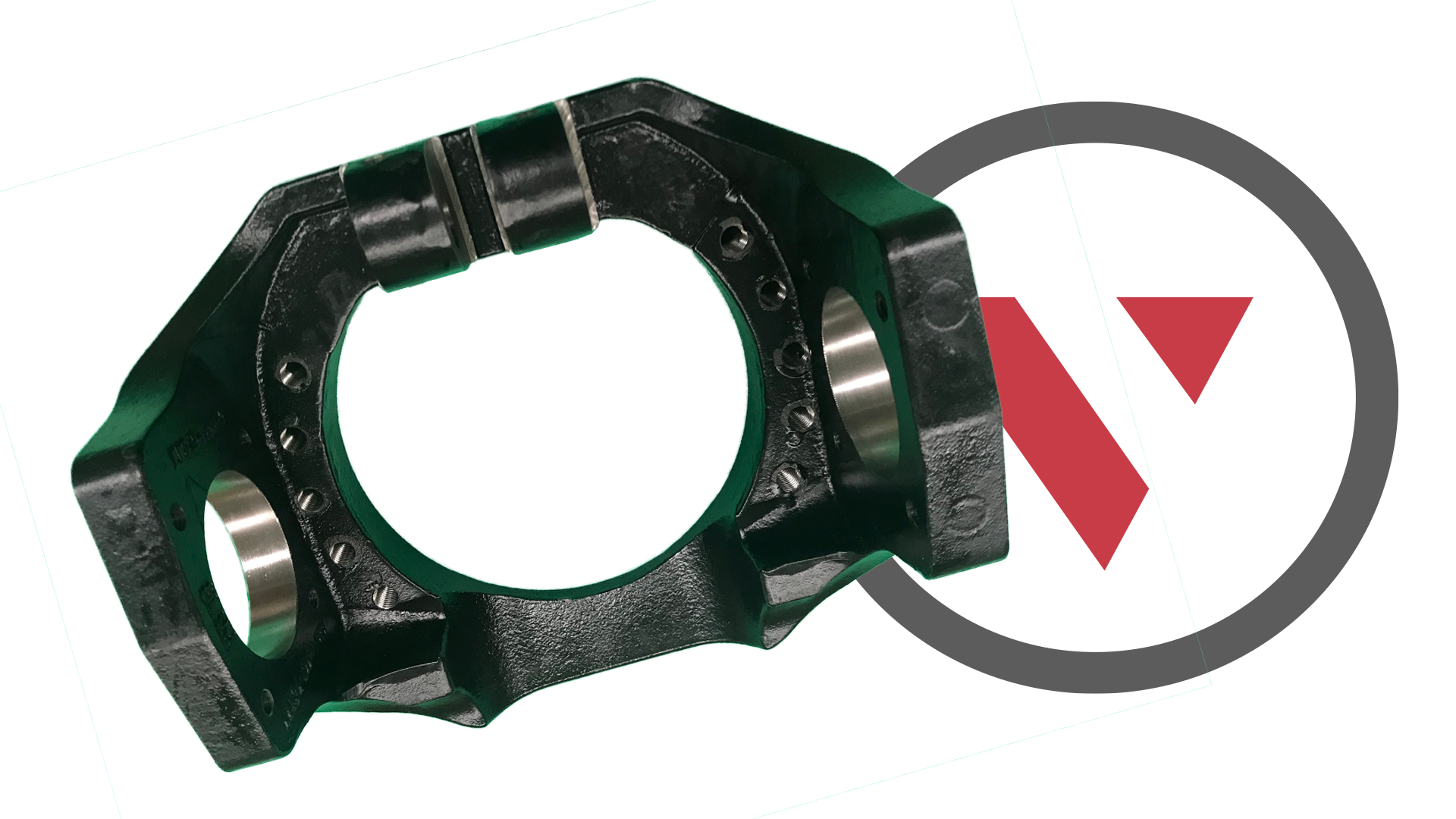

Viable was approached by a representative of a Chinese company to rectify a large number of non conforming machined components that arrived in the UK and had been delivered to the customer’s site.

After liaising with the customer’s engineers, it was established the problem was due to an incorrect machined wall thickness measurement, thus making the component non conforming.

With agreement from the supplier, Viable established a recovery exercise and rectified this problem quickly, enabling the component parts to be used by the customer and aid the supply chain management.

How we helped

Viable minimised the replacement of parts via the rework of existing components, ultimately, saving money.

Using our machining service we rectified a critical wall thickness discrepancy via the milling of excess material, thus, bringing the components dimensions down to the required drawing tolerances.

After an initial trial batch, the customer agreed on the full rectification of defective components.

Viable will always endeavor to find a cost effective answer to our clients problems.

What our client said

“We have used Viable on several occasions and find their flexibility and response times to be excellent.

Viable has a wealth of knowledge and experience, meaning that efficient solutions can normally be found to solve complex problems.”